Tools of the trade

This is a felted wool bushing material. I have three uses for this material. I believe it comes from England although I have a US supplier.

I use the bushing felt in the bottom of the holes cut into the actionboard to receive the buttons. they give the buttons a nice firm, yet cushioned feel. The buttons are entirely surrounded by the felt and touch nothing else in the instrument.

These are the springs and levers I make here in the shop for the concertinas I build. Not available in any store!

I use to bend them by hand:

http://hmi.homewood.net/video/test2.MOV

That was slow.

Now I have built a spring makinging gizmo:

http://hmi.homewood.net/video/springbender.MOV

It is slow as well.

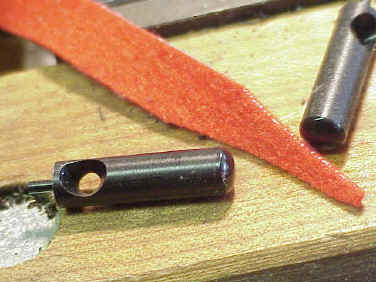

Can't buy the buttons either,

they are cut one at a time on a miniature lathe.

I typically use 1/4" Delrin for my buttons. Delrin has very little friction, is light and machines nicely. I make concertinas with brass buttons as well. See http://hmi.homewood.net/blak/

First step completed

I jig up a #3 centre drill

to cut a chamfered hole in each button. I usually break two or

three so I cut a few extra just in case.

they look like this.