|

|

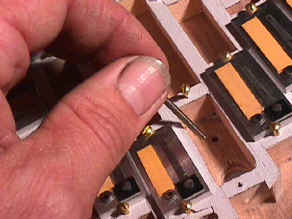

| Button should move up and down easily |

look for obstructions or too tight button bushings; they should be snug

but allow the button to move up and down easily. |

|

|

| set metal end back on the frame and try each button to see that you have

correctly aligned the buttons. |

|

|

|

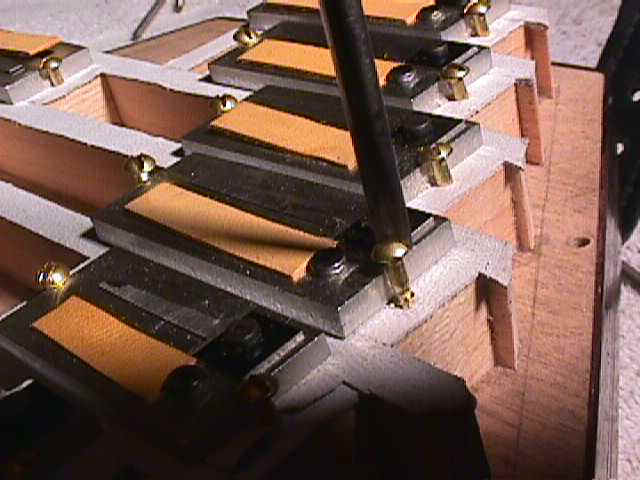

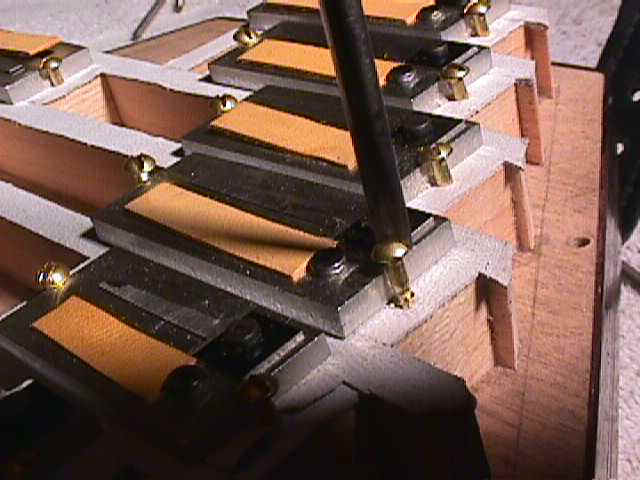

| replace the long machine screw |

Start all screws by first turning the screw backwards while gently

pressing with the screwdriver, feel for a "click" as the threads engage.

Try not to "cross thread" the screw. |

|

|

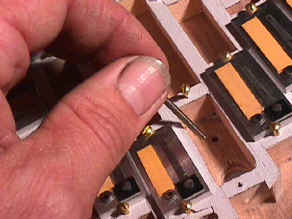

| return the reed to its reed pan |

replace the small wood screw |

|

|

| snug the screw, no need to over tighten |

don't forget to snug both ends, or air will leak. |

|

|

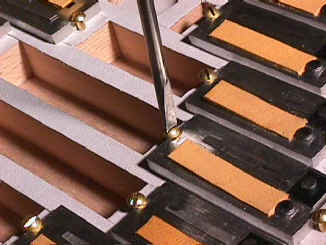

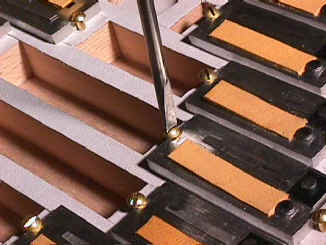

| replace the ends on the bellows frame |

Replace each screw back to its original location |

|

|

| Gently turn each screw backwards, feel for the "click" as the

threads engage. Lightly snug each screw. Do not attempt to tighten all the way. |

This is important. Know that screws serve only to secure and

hold the ends in place; they are not to be used as a "winch" to drive the ends

into submission! With one hand squeezing the bellow together with a firm grip, snug

the screw till it is just tight. Move on to the next screw until you have tightened all

six. |

|

Questions? call me at 205-879-4868 hmi@scott.net

Homewood Musical

3027 Central Ave, Birmingham, Alabama 35209

|

| Replace thumb screw and check your work |

|